The Ultimate JOHN DEERE® Rubber Track Reference Guide

Farming operations across the world are unique. Working closely with track tractor and combines owners, We have created an extensive line of tracks to fit virtually any application. This guide is intended to help you better understand the complete line of tracks for tractors and provide helpful recommendations for the best use of each type.

All tractor tracks are built by us using an exclusive manufacturing process that keeps each component in place, resulting in a stronger track.

To choose the best track for your operation, carefully consider your applications:

■ Cropping patterns

■ Typical field conditions, soil types and terrain

■ Implements used

■ Amount of road travel

With knowledge of your local conditions and applications, we can help you use this guide to find the best track for your operation.

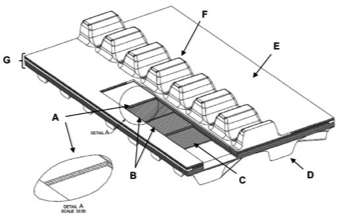

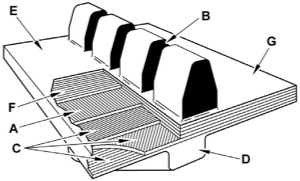

Our tracks are constructed using a combination of natural and synthetic rubber in combination with steel reinforcing plies and continuous wound main cables. The main cables give the track tension strength. The bias and reinforcement plies protect the main cables, provide internal track alignment, and further increase lateral stiffness to better distribute loads across the track width. The tread bars are designed with specific shapes, with each shape giving a distinct performance advantage in specific applications.

Track alignment should be checked periodically (per machine operator manual instructions), especially during break-in. Alignment may change throughout the life of the machine due to track or track system component wear. Significant misalignment may result in heating and accelerated wear to one side of the guide or drive lug, as well as cause heat related damage to the midrollers and drive wheels.

The most common way to verify alignment is through use of a shim to check guide or drive lug clearance with the front midrollers by driving a fixed distance and coasting to a stop on a flat hard surface. See your machine operators manual for proper procedures for checking and adjusting alignment on your specific platform.

Temperature differential between the inner and outer surface of a guide or drive lug can also be used as a secondary step to refine the alignment, if needed. However, it is acceptable to have some temperature differential remaining once the machine passes the shim check. As long as the temperature differential is maintained at less than 20 oC (40 oF), as measured during road transport, no further alignment adjustment should be required.

Tracks can pull more – so reduce loads at low speeds

Tracks deliver much less slip in high torque, low speed operations. Follow the operator’s manual guidelines and stay above the minimum speed for full load operation. Never exceed the maximum ballasted weight in order to gain more traction in lower gears.

Ballast the tractor to achieve no less than 2-5% slip under heavy pull conditions. In addition, the best track performance comes from even weight distribution along the entire track length. Correct ballast will result in reduced tread bar wear, longer rolling component life, less compaction, and improved ride and turning performance.

In a friction drive system, proper track tension is critical to achieve maximum tractive performance. Inadequate tension can allow more material between the track and wheels, allow track to drive wheel slip, and increase the potential for untracking.

Track systems are designed to allow for some amounts of material to pass between the drive wheel and track. However, uncompressable objects will cause very high localized track loading, which can result in chips, chunks, and tears in the track and undercarriage components. In addition, excessive material build-up inside the undercarriage can cause the tensioning system to run out of recoil. If recoil is used up, track tearing can occur. If a tractor becomes stuck, always dig out the undercarriage and pull the machine out backwards to avoid track damage.

Track machines have certain maneuvers that should be approached with care. One example is during a transition from a sloped to a flat area, especially if transitioning at a diagonal. If dynamic turning is attempted during the transition, the risk is higher for untracking to occur. Operate at low speeds, and avoid turning, to minimize the risk of untracking in these situations.

The 8RT series offers an all new undercarriage design, and incorporates an air suspension system that improves ride, reduces vibration, and reduces maintenance costs.The tracks are tensioned by a nitrogen accumulator and hydraulic cylinder. Track tension pressure should be maintained at 2950 psi (20,339 kPa). This creates a track tension at approx. 16,000 lbs (7257 kg). Track tension pressure can be monitored utilizing the tractor monitor screen on most 8RT Series Tractors. High and low pressure alarms warn the operator of potential issues.

Correct track tension pressure should be maintained to avoid either overtension or track to drive wheel slippage Refer to the Operation and Maintenance Manual (OMM) for procedures to properly maintain track tension.

8RT Models [354 in (8992 mm) Track Circumference]:

8295RT 8310RT 8320RT

8335RT 8345RT 8360RT

8370RT

Every operation demands efficiency and reliability. In order to balance track life, flotation and compaction, we offer a range of tracks to customize your tractor to your operation.

The tracks are tensioned by a nitrogen accumulator and hydraulic cylinder. Track tension pressure should be maintained at 2950 psi (20,339 kPa). This creates a track tension of approximately 22,000 lbs (10,000kg). High and low pressure alarms warn the operator of potential issues.

Correct track tension pressure should be maintained to avoid either overtension or track to drive wheel slippage. Reference the tractor’s Operation and Maintenance Manual (OMM) for procedures to properly maintain track tension.

9000T-9020T Models

[378 in (9601 mm) Track Circumference]:

9300T 9400T

9320T 9420T 9520T 9620T

The 9030T-9RT series offers an all new undercarriage design, and incorporates an air suspension system that improves ride, reduces vibration, and reduces maintenance costs.

The tracks are tensioned by a nitrogen accumulator and hydraulic cylinder. Track tension pressure should be maintained at 2950 psi (20,339 kPa). This creates a track tension of approximately 26,000 lbs (11,800 kg). Track tension pressure can be monitored utilizing the tractor monitor screen on most 9030T/9RT Series Tractors. High and low pressure alarms warn the operator of potential issues.

Correct track tension pressure should be maintained to reduce damage to the tracks. Reference the tractor’s Operation and Maintenance Manual (OMM) for procedures to properly maintain track tension.

9030T-9RT Models [387 in (9830 mm) Track Circumference]:

9430T 9530T 9630T

9460RT 9470RT 9510RT

9520RT 9560RT 9570RT

9460RT

Scraper Special 9470RT

Scraper special 9510RT

Scraper Special

9520RT

Scraper special 9560RT

Scraper Special 9570RT

Scraper special

The 8RX series offers a wide range of track and axle configurations, tread spacing options and belt widths. Axle tread spacing can be set at 76″ (193cm), 80″ (203.2cm), 88″ (223.5cm), or 120″

(304.8cm) gauge widths.

The 9RX Wide Series offers an all new 4 track positive drive under- carriage design

The 9RX Narrow Series Tractors are also equipped with designed narrow undercarriages which are ideal for the 22-inch, 30-inch, and 40-inch row-crop applications.

For longest life, tracks should be repaired when:

■ Cables are exposed in the carcass – Cables loose

or protruding from the carcass should be trimmed to prevent damage to other components.

■ Guide lugs are missing – Bolt-on guide lug kits are available

■ Loose tread bar – Loose portion of the tread bar should be trimmed to prevent damage to other components.

For best performance, tracks should be replaced when:

■ Tread bar height is less than 0.5 in (12 mm)

■ Track to ground slippage consistently exceeds 10%

■ Several (more than 3) tread bars are missing in a row

■ Multiple (more than 5) guide lugs are missing consecutively

■ 1 or more drive lugs are missing

■ Guide lugs have excessive wear (50% of guide lugs is worn)

■ De-tracking occurs due to worn or missing guide lugs

■ The main cables have torn in the wheel path (Tear across the width of the carcass)

■ Cables are showing on the inside surface of the track

■ Drive wheel to track slippage is excessive due to missing ID rubber or rubber surface is glazed/hardened from drive wheels slipping.