The Ultimate 2026 AGCO® Challenger® Fendt® and Massey Ferguson® Tractors and Combines Rubber Track Reference Guide

Table of Contents

1. Introduction and Track Terminology

Farming operations across the world are unique. Working closely with track tractor and combines owners, We have created an extensive line of tracks to fit virtually any application. This guide is intended to help you better understand the complete line of tracks for tractors and provide helpful recommendations for the best use of each type.

All tractor tracks are built by us using an exclusive manufacturing process that keeps each component in place, resulting in a stronger track.

To choose the best track for your operation, carefully consider your applications:

■ Cropping patterns

■ Typical field conditions, soil types and terrain

■ Implements used

■ Amount of road travel

With knowledge of your local conditions and applications, we can help you use this guide to find the best track for your operation.

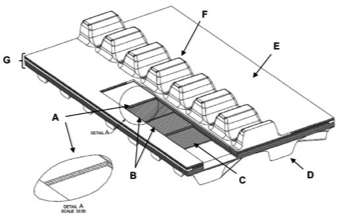

1.1 Agricultural Track Terminology

2. TRACK MACHINE OPERATIONAL GUIDELINES

2.1 New Track Break-In

Tracks should be operated in dry soil as soon as possible after new installation Track guide and drive lugs, especially on new machines, benefit from correct break-in procedures. Correct break-in through immediate introduction of the track into dry soil helps reduce the initial amount of heat generation. Track components undergo a polishing-in process during the break-in period. During this time, flash is worn from wheel edges and a smooth steel to rubber interface is developed. New rubber surfaces benefit from frequent contact with the soil, which acts as a dry lubricant, and will facilitate smooth break-in and minimize heat during break-in activities. Improper break-in may result in scuffs and poor appearance to the side of the guide or drive lugs, This will polish over once proper break-in procedures are resumed. Any significant transport distances before introduction in the field should be avoided or heat related damage to track and system components can result.

2.2 Maintain Track Alignment

2.3 Correct Operational Techniques

Use proper amounts of ballast

Maintain correct track tension

Keep material out of the track

Use care when crossing ditches or transitions

3. CHALLENGER MT700 SERIES (A THRU E SERIES) TRACK SELECTION (348 IN TRACK CIRCUMFERENCE)

| AGCO P/N | P/N | TRACK WIDTH | CARCASS THICKNESS | GUIDE LUGS | TREAD BARS | TREAD BAR HEIGHT |

|---|---|---|---|---|---|---|

| 581847D1 | F18AR02927 | 18 in (457 mm) | 1.45 in (37 mm) | 46 | 130 | 1.5 in (38 mm) |

| 581852D1 | F25AR02992 | 25 in (635 mm) | 1.45 in (37 mm) | 46 | 130 | 1.5 in (38 mm) |

| 581842D1 | F16AR02921 | 16 in (406 mm) | 1.45 in (37 mm) | 46 | 46 (RH) | 2.7 in (68 mm) |

| 581843D1 | F16AR02922 | 16 in (406 mm) | 1.45 in (37 mm) | 46 | 46 (LH) | 2.7 in (68 mm) |

| 581846D1 | F18AR02926 | 18 in (457 mm) | 1.45 in (37 mm) | 46 | 92 | 2.7 in (68 mm) |

| - | F24AR02868 | 24 in (610 mm) | 1.45 in (37 mm) | 46 | 92 | 2.7 in (68 mm) |

| 581851D1 | F25AR02991 | 25 in (635 mm) | 1.45 in (37 mm) | 46 | 92 | 2.7 in (68 mm) |

| 581855D1 | F30AR02995 | 30 in (762 mm) | 1.45 in (37 mm) | 46 | 92 | 2.7 in (68 mm) |

| 581858D1 | F34AR03101 | 34 in (864 mm) | 1.45 in (37 mm) | 46 | 92 | 2.7 in (68 mm) |

| - | F25AR02928 | 25 in (635 mm) | 1.45 in (37 mm) | 46 | 92 | 2.7 in (68 mm) |

| - | F30AR02929 | 30 in (762 mm) | 1.45 in (37 mm) | 46 | 92 | 2.7 in (68 mm) |

| 581838D1 | E14AR02908 | 14.5 in (356 mm) | 1.73 in (44 mm) | 46 | 46 (RH) | 3.0 in (75 mm) |

| 581839D1 | E14AR02909 | 14.5 in (356 mm) | 1.73 in (44 mm) | 46 | 46 (LH) | 3.0 in (75 mm) |

| 581844D1 | E16AR02919 | 16 in (406 mm) | 1.73 in (44 mm) | 46 | 46 (RH) | 3.0 in (75 mm) |

| 581845D1 | E16AR02920 | 16 in (406 mm) | 1.73 in (44 mm) | 46 | 46 (LH) | 3.0 in (75 mm) |

| - | E18AR02924 | 18 in (457 mm) | 1.73 in (44 mm) | 46 | 46 (RH) | 3.0 in (75 mm) |

| - | E18AR02925 | 18 in (457 mm) | 1.73 in (44 mm) | 46 | 46 (LH) | 3.0 in (75 mm) |

| 581848D1 | E18AR02923 | 18 in (457 mm) | 1.73 in (44 mm) | 46 | 92 | 3.0 in (75 mm) |

| 581853D1 | E25AR02990 | 25 in (635 mm) | 1.65 in (42 mm) | 46 | 92 | 3.0 in (75 mm) |

| 581856D1 | E30AR02994 | 30 in (762 mm) | 1.65 in (42 mm) | 46 | 92 | 3.0 in (75 mm) |

| 581854D1 | E25AR02989 | 25 in (635 mm) | 1.65 in (42 mm) | 46 | 92 | 2.7 in (68 mm) |

| 581857D1 | E30AR02993 | 30 in (762 mm) | 1.65 in (42 mm) | 46 | 92 | 2.7 in (68 mm) |

| 581859D1 | E34AR03102 | 34 in (864 mm) | 1.65 in (42 mm) | 46 | 92 | 2.7 in (68 mm) |

3.1 Challenger MT700 Series Track Cross Reference (Current Tracks) 348 in Track Circumference

| CURRENT AGCO P/N | CURRENT P/N | TRACK WIDTH | PREVIOUS P/N | PREVIOUS AGCO P/N |

|---|---|---|---|---|

| ACP0316930 | A16AR03293 | 16 in (406 mm) | - | - |

| ACP0316940 | A18AR03294 | 18 in (457 mm) | - | - |

| ACP0316950 | A25AR03295 | 25 in (635 mm) | - | - |

| ACP0316960 | A30AR03306 | 30 in (762 mm) | - | - |

| 581847D1 | F18AR02927 | 18 in (457 mm) | 695-1837 | 563755D1 |

| 581852D1 | F25AR02992 | 25 in (635 mm) | 695-2532 | 563761D1 |

| 581842D1 | F16AR02921 | 16 in (406 mm) | 635-1641 | 554106D1 |

| 581843D1 | F16AR02922 | 16 in (406 mm) | 635-1642 | 554107D1 |

| 581848D1 | E18AR02923 | 18 in (457 mm) | 635-1840 | 563754D1 |

| - | F24AR02868 | 24 in (610 mm) | - | - |

| 581851D1 | F25AR02991 | 25 in (635 mm) | 635-2533 | 563760D1 |

| 581855D1 | F30AR02995 | 30 in (762 mm) | 635-3060 | 563764D1 |

| - | F25AR02928 | 25 in (635 mm) | - | - |

| - | F30AR02929 | 30 in (762 mm) | - | - |

| 581838D1 | E14AR02908 | 14.5 in (356 mm) | 655-1412 | 554104D1 |

| 581839D1 | E14AR02909 | 14.5 in (356 mm) | 655-1413 | 554105D1 |

| 581844D1 | E16AR02919 | 16 in (406 mm) | 655-1639 | 554108D1 |

| 581845D1 | E16AR02920 | 16 in (406 mm) | 655-1640 | 554109D1 |

| - | E18AR02924 | 18 in (457 mm) | 655-1834 | - |

| - | E18AR02925 | 18 in (457 mm) | 655-1835 | - |

| 581848D1 | E18AR02923 | 18 in (457 mm) | 655-1826 | 563753D1 |

| 581853D1 | E25AR02990 | 25 in (635 mm) | 655-2528 | 563759D1 |

| 581856D1 | E30AR02994 | 30 in (762 mm) | 655-3061 | 563763D1 |

| 581854D1 | E25AR02989 | 25 in (635 mm) | 655-2536 | 563758D1 |

| 581857D1 | E30AR02993 | 30 in (762 mm) | 655-3062 | 563762D1 |

3.2 Challenger MT700 Series Track Cross Reference (Older Tracks) 348 in Track Circumference

| PREVIOUS P/N | WIDTH | PREVIOUS AGCO P/N |

|---|---|---|

| 655-1408, 655-1412 | 14 in | 1R-1381, 508600D1, 554104D1 |

| 655-1409, 655-1413 | 14 in | 1R-1380, 508601D1, 554105D1 |

| 635-1625, 635-1641 | 16 in | 1R-1383, 508602D1, 554106D1 |

| 635-1626, 635-1642 | 16 in | 1R-1382, 508603D1, 554107D1 |

| 695-1623, 695-1643 | 16 in | 1R-1384, 554094D1 |

| 695-1624, 695-1644 | 16 in | 1R-1385, 554095D1 |

| 655-1621, 655-1639 | 16 in | 1R-1386, 508606D1, 554108D1 |

| 655-1622, 655-1640 | 16 in | 1R-1387, 508607D1, 554109D1 |

| - | 16 in | 520016D1 |

| - | 16 in | 520017D1 |

| 635-1815, 635-1840 | 18 in | 1R-1259, 554084D1 |

| 695-1818, 695-1837 | 18 in | 1R-1258, 554083D1 |

| 655-1817, 695-1826 | 18 in | 1R-1358, 502057D1, 554098D1 |

| - | 18 in | 520018D1 |

| 655-1834 | 18 in | - |

| 655-1835 | 18 in | - |

| 635-2004, 635-2006 | 20 in | 1R-1260, 554085D1 |

| 655-2005, 655-2007 | 20 in | 1R-1359, 502058D1, 554099D1 |

| 635-2521, 635-2533 | 25 in | 1R-1262, 554087D1 |

| 695-2520, 695-2532 | 25 in | 1R-1261, 554086D1 |

| 655-2522, 655-2528 | 25 in | 1R-1320, 554092D1 |

| 655-2523, 655-2536 | 25 in | 502597D1, 554100D1 |

| 635-3028, 635-3060 | 30 in | 1R-1263, 554088D1 |

| 655-3030, 655-3061 | 30 in | 1R-1321, 554093D1 |

| 655-3044, 655-3062 | 30 in | 518708D1, 554111D1 |

4. CHALLENGER MT700 SERIES TRACK SELECTION (359 IN TRACK CIRCUMFERENCE)

| AGCO P/N | P/N | TRACK WIDTH | CARCASS THICKNESS* | GUIDE LUGS | TREAD BARS | TREAD BAR HEIGHT |

|---|---|---|---|---|---|---|

| 588709D1 | F16BY03127 | 16 in | 1.45 in (37 mm) | 48 | 47 | 2.7 in (68 mm) |

| 588710D1 | F16BY03128 | 16 in | 1.45 in (37 mm) | 48 | 47 | 2.7 in (68 mm) |

| 588711D1 | F16BY03227 | 16 in | 1.45 in (37 mm) | 48 | 66 | 1.6 in (41 mm) |

| 588712D1 | F16BY03228 | 16 in | 1.45 in (37 mm) | 48 | 66 | 1.6 in (41 mm) |

| 588715D1 | F18BY03229 | 18 in | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| 588716D1 | F18BY03230 | 18 in | 1.45 in (37 mm) | 48 | 132 | 1.6 in (41 mm) |

| 588718D1 | F20BY03231 | 20 in | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| N/A | F24BY03409 | 24 in | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| 588622D1 | F25BY03114 | 25 in | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| 588720D1 | F25BY03233 | 25 in | 1.45 in (37 mm) | 48 | 132 | 1.6 in (41 mm) |

| 588723D1 | F30BY03234 | 30 in | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| 588726D1 | F34BY03235 | 34 in | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| N/A | F25BY03410 | 25 in | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| N/A | F30BY03411 | 30 in | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| 588707D1 | E14BY03116 | 14 in | 1.73 in (44 mm) | 48 | 47 | 3.0 in (75 mm) |

| 588708D1 | E14BY03117 | 14 in | 1.73 in (44 mm) | 48 | 47 | 3.0 in (75 mm) |

| 588713D1 | E16BY03201 | 16 in | 1.73 in (44 mm) | 48 | 47 | 3.0 in (75 mm) |

| 588714D1 | E16BY03202 | 16 in | 1.73 in (44 mm) | 48 | 47 | 3.0 in (75 mm) |

| 588717D1 | E18BY03203 | 18 in | 1.73 in (44 mm) | 48 | 94 | 3.0 in (75 mm) |

| 588719D1 | E20BY03232 | 20 in | 1.65 in (42 mm) | 48 | 94 | 3.0 in (75 mm) |

| 588721D1 | E25BY03115 | 25 in | 1.65 in (42 mm) | 48 | 94 | 2.7 in (68 mm) |

| 588722D1 | E25BY03204 | 25 in | 1.65 in (42 mm) | 48 | 94 | 3.0 in (75 mm) |

| 588724D1 | E30BY03205 | 30 in | 1.65 in (42 mm) | 48 | 94 | 2.7 in (68 mm) |

| 588725D1 | E30BY03206 | 30 in | 1.65 in (42 mm) | 48 | 94 | 3.0 in (75 mm) |

| 588727D1 | E34BY03207 | 34 in | 1.65 in (42 mm) | 48 | 94 | 2.7 in (68 mm) |

5. FENDT 900 VARIO MT SERIES TRACK SELECTION (359 IN TRACK CIRCUMFERENCE)

| AGCO P/N | P/N | TRACK WIDTH | CARCASS THICKNESS | GUIDE LUGS | TREAD BARS | TREAD BAR HEIGHT |

|---|---|---|---|---|---|---|

| 588709D1 | F16BY03127 | 16 | 1.45 in (37 mm) | 48 | 47 | 2.7 in (68 mm) |

| 588710D1 | F16BY03128 | 16 | 1.45 in (37 mm) | 48 | 47 | 2.7 in (68 mm) |

| 588711D1 | F16BY03227 | 16 | 1.45 in (37 mm) | 48 | 66 | 1.6 in (41 mm) |

| 588712D1 | F16BY03228 | 16 | 1.45 in (37 mm) | 48 | 66 | 1.6 in (41 mm) |

| 588715D1 | F18BY03229 | 18 | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| 588716D1 | F18BY03230 | 18 | 1.45 in (37 mm) | 48 | 132 | 1.6 in (41 mm) |

| 588718D1 | F20BY03231 | 20 | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| N/A | F24BY03409 | 24 | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| 588622D1 | F25BY03114 | 25 | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| 588720D1 | F25BY03233 | 25 | 1.45 in (37 mm) | 48 | 132 | 1.6 in (41 mm) |

| 588723D1 | F30BY03234 | 30 | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| 588726D1 | F34BY03235 | 34 | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| N/A | F25BY03410 | 25 | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| N/A | F30BY03411 | 30 | 1.45 in (37 mm) | 48 | 94 | 2.7 in (68 mm) |

| 588707D1 | E14BY03116 | 14 | 1.73 in (44 mm) | 48 | 47 | 3.0 in (75 mm) |

| 588708D1 | E14BY03117 | 14 | 1.73 in (44 mm) | 48 | 47 | 3.0 in (75 mm) |

| 588713D1 | E16BY03201 | 16 | 1.73 in (44 mm) | 48 | 47 | 3.0 in (75 mm) |

| 588714D1 | E16BY03202 | 16 | 1.73 in (44 mm) | 48 | 47 | 3.0 in (75 mm) |

| 588717D1 | E18BY03203 | 18 | 1.73 in (44 mm) | 48 | 94 | 3.0 in (75 mm) |

| 588719D1 | E20BY03232 | 20 | 1.65 in (42 mm) | 48 | 94 | 3.0 in (75 mm) |

| 588721D1 | E25BY03115 | 25 | 1.65 in (42 mm) | 48 | 94 | 2.7 in (68 mm) |

| 588722D1 | E25BY03204 | 25 | 1.65 in (42 mm) | 48 | 94 | 3.0 in (75 mm) |

| 588724D1 | E30BY03205 | 30 | 1.65 in (42 mm) | 48 | 94 | 2.7 in (68 mm) |

| 588725D1 | E30BY03206 | 30 | 1.65 in (42 mm) | 48 | 94 | 3.0 in (75 mm) |

| 588727D1 | E34BY03207 | 34 | 1.65 in (42 mm) | 48 | 94 | 2.7 in (68 mm) |

5.1 Challenger MT700/Fendt 900 Vario MT Series Track Cross Reference (Current Tracks) 359 in Track Circumference

| CURRENT AGCO P/N | CURRENT P/N | TRACK WIDTH | SERVICEABLE AGCO TRACK |

|---|---|---|---|

| N/A | A16BY03405 | 16 | - |

| N/A | A18BY03406 | 18 | - |

| N/A | A25BY03407 | 25 | - |

| N/A | A30BY03408 | 30 | - |

| 588709D1 | F16BY03127 | 16 | 601902D1 |

| 588710D1 | F16BY03128 | 16 | 601903D1 |

| 588711D1 | F16BY03227 | 16 | 601904D1 |

| 588712D1 | F16BY03228 | 16 | 601905D1 |

| 588715D1 | F18BY03229 | 18 | 601908D1 |

| 588716D1 | F18BY03230 | 18 | 601909D1 |

| 588718D1 | F20BY03231 | 20 | 601911D1 |

| N/A | F24BY03409 | 24 | - |

| 588622D1 | F25BY03114 | 25 | 601913D1 |

| 588720D1 | F25BY03233 | 25 | 601914D1 |

| 588723D1 | F30BY03234 | 30 | 601917D1 |

| 588726D1 | F34BY03235 | 34 | 601920D1 |

| N/A | F25BY03410 | 25 | - |

| N/A | F30BY03411 | 30 | - |

| 588707D1 | E14BY03116 | 14 | - |

| 588708D1 | E14BY03117 | 14 | - |

| 588713D1 | E16BY03201 | 16 | 601906D1 |

| 588714D1 | E16BY03202 | 16 | 601907D1 |

| 588717D1 | E18BY03203 | 18 | 601910D1 |

| 588719D1 | E20BY03232 | 20 | 601912D1 |

| 588721D1 | E25BY03115 | 25 | 601915D1 |

| 588722D1 | E25BY03204 | 25 | 601916D1 |

| 588724D1 | E30BY03205 | 30 | 601918D1 |

| 588725D1 | E30BY03206 | 30 | 601919D1 |

| 588727D1 | E34BY03207 | 34 | 601921D1 |

5.2 Challenger MT700/Fendt 900 Vario MT Series vs Application Matrix (Track Width)

| CATEGORY | APPLICATION/OPERATION DESCRIPTION | 14 in (356 mm) |

16 in (406 mm) |

18 in and 24 in (457 mm and 610 mm) |

25 in, 30 in, and 34 in (635 mm, 762 mm, and 863 mm) |

|---|---|---|---|---|---|

| Field Conditions | Minimal ground disturbance/Berming | Not recommended | OK to use | OK to use | OK to use |

| Extreme cold | Not recommended | OK to use | OK to use | OK to use | |

| In furrow applications | OK to use | OK to use | OK to use | Not recommended | |

| Short fields, applications requiring a lot of turning | OK to use | OK to use | OK to use | OK to use | |

| Flat land farming, slopes up to 10% | OK to use | OK to use | OK to use | OK to use | |

| Moderate side slope applications, slopes from 10 to 25% | OK to use | OK to use | OK to use | OK to use | |

| Severe side slope applications, slopes greater than 25% | Not recommended | Not recommended | Not recommended | OK to use | |

| Road Travel | Small amount of roading, most field and travel distances within 5 mile radius | OK to use | OK to use | OK to use | OK to use |

| Moderate amount of roading, most field and travel distances between 5 and 10 mile radius | OK to use | OK to use | OK to use | OK to use | |

| High amount of roading, typically travel in excess of 10 miles | Not recommended | OK to use | OK to use | OK to use | |

| Applications | Primary tillage (deep ripping, chisel plow, etc.) | Not recommended | Not recommended | OK to use | Recommended |

| Secondary tillage (field cultivator, disk, roller, etc.) | Not recommended | Not recommended | OK to use | OK to use | |

| Fully mounted roll over plow | Not recommended | Not recommended | OK to use | Recommended | |

| Row crop planter | OK to use | OK to use | OK to use | OK to use | |

| Air seeder | Not recommended | Not recommended | OK to use | OK to use | |

| Manure tank | Not recommended | Not recommended | OK to use | OK to use | |

| Grain cart | Not recommended | Not recommended | OK to use | OK to use | |

| Tile plow | Not recommended | Not recommended | OK to use | OK to use | |

| Spraying | OK to use | OK to use | OK to use | OK to use | |

| Hay baling | Not recommended | OK to use | OK to use | OK to use | |

| Stalk chopper/Brush hog | OK to use | OK to use | OK to use | OK to use | |

| Vegetable bedder | OK to use | OK to use | OK to use | OK to use | |

| Front blade - Silage | Not recommended | Not recommended | OK to use | OK to use | |

| Forage harvestor | OK to use | OK to use | OK to use | OK to use | |

| Snow grooming | Not recommended | Not recommended | OK to use | OK to use | |

| Agricultural scraper | Not recommended | Not recommended | OK to use | OK to use | |

| Commercial scraper | Not recommended | Not recommended | OK to use | OK to use | |

| Forestry | Not recommended | Not recommended | OK to use | OK to use | |

| Non-agricultural applications | Not recommended | Not recommended | OK to use | OK to use |

6. CHALLENGER MT800 TRACK SELECTION

| AGCO P/N | P/N | TRACK WIDTH | CARCASS THICKNESS | GUIDE LUGS | TREAD BARS | TREAD BAR HEIGHT |

|---|---|---|---|---|---|---|

| - | F25AS03179 | 25.5 in (648 mm) | 1.45 in (37 mm) | 52 | 100 | 2.7 in (68 mm) |

| 581861D1 | F27AS02998 | 27.5 in (699 mm) | 1.45 in (37 mm) | 52 | 100 | 2.7 in (68 mm) |

| 581864D1 | F30AS03001 | 30 in (762 mm) | 1.45 in (37 mm) | 52 | 100 | 2.7 in (68 mm) |

| 581868D1 | F36AS03003 | 36 in (914 mm) | 1.45 in (37 mm) | 52 | 100 | 2.7 in (68 mm) |

| - | F27AS02931 | 27.5 in (699 mm) | 1.45 in (37 mm) | 52 | 100 | 2.7 in (68 mm) |

| - | F30AS02933 | 30 in (762 mm) | 1.45 in (37 mm) | 52 | 100 | 2.7 in (68 mm) |

| 581860D1 | E18AS02930 | 18 in (457 mm) | 1.73 in (44 mm) | 52 | 100 | 3.0 in (75 mm) |

| 581862D1 | E27AS02997 | 27.5 in (699 mm) | 1.65 in (42 mm) | 52 | 100 | 3.0 in (75 mm) |

| 581866D1 | E30AS03000 | 30 in (762 mm) | 1.65 in (42 mm) | 52 | 100 | 3.0 in (75 mm) |

| 581870D1 | E36AS03002 | 36 in (914 mm) | 1.65 in (42 mm) | 52 | 100 | 3.0 in (75 mm) |

| - | E25AS03180 | 25.5 in (648 mm) | 1.65 in (42 mm) | 52 | 100 | 2.7 in (68 mm) |

| 581863D1 | E27AS02996 | 27.5 in (699 mm) | 1.65 in (42 mm) | 52 | 100 | 2.7 in (68 mm) |

| 581867D1 | E30AS02999 | 30 in (762 mm) | 1.65 in (42 mm) | 52 | 100 | 2.7 in (68 mm) |

| 581865D1 | E30AS02932 | 30 in (762 mm) | 1.73 in (44 mm) | 52 | 100 | 2.2 in (57 mm) |

| 581869D1 | E36AS02934 | 36 in (914 mm) | 1.73 in (44 mm) | 52 | 100 | 2.2 in (57 mm) |

7. FENDT 1100 MT/1100 VARIO MT TRACK SELECTION

| AGCO P/N | P/N | TRACK WIDTH | CARCASS THICKNESS | GUIDE LUGS | TREAD BARS | TREAD BAR HEIGHT |

|---|---|---|---|---|---|---|

| - | F25AS03179 | 25.5 in (648 mm) | 1.45 in (37 mm) | 52 | 100 | 2.7 in (68 mm) |

| 581861D1 | F27AS02998 | 27.5 in (699 mm) | 1.45 in (37 mm) | 52 | 100 | 2.7 in (68 mm) |

| 581864D1 | F30AS03001 | 30 in (762 mm) | 1.45 in (37 mm) | 52 | 100 | 2.7 in (68 mm) |

| 581868D1 | F36AS03003 | 36 in (914 mm) | 1.45 in (37 mm) | 52 | 100 | 2.7 in (68 mm) |

| - | F27AS02931 | 27.5 in (699 mm) | 1.45 in (37 mm) | 52 | 100 | 2.7 in (68 mm) |

| - | F30AS02933 | 30 in (762 mm) | 1.45 in (37 mm) | 52 | 100 | 2.7 in (68 mm) |

| 581860D1 | E18AS02930 | 18 in (457 mm) | 1.73 in (44 mm) | 52 | 100 | 3.0 in (75 mm) |

| 581862D1 | E27AS02997 | 27.5 in (699 mm) | 1.65 in (42 mm) | 52 | 100 | 3.0 in (75 mm) |

| 581866D1 | E30AS03000 | 30 in (762 mm) | 1.65 in (42 mm) | 52 | 100 | 3.0 in (75 mm) |

| 581870D1 | E36AS03002 | 36 in (914 mm) | 1.65 in (42 mm) | 52 | 100 | 3.0 in (75 mm) |

| - | E25AS03180 | 25.5 in (648 mm) | 1.65 in (42 mm) | 52 | 100 | 2.7 in (68 mm) |

| 581863D1 | E27AS02996 | 27.5 in (699 mm) | 1.65 in (42 mm) | 52 | 100 | 2.7 in (68 mm) |

| 581867D1 | E30AS02999 | 30 in (762 mm) | 1.65 in (42 mm) | 52 | 100 | 2.7 in (68 mm) |

| 581865D1 | E30AS02932 | 30 in (762 mm) | 1.73 in (44 mm) | 52 | 100 | 2.2 in (57 mm) |

| 581869D1 | E36AS02934 | 36 in (914 mm) | 1.73 in (44 mm) | 52 | 100 | 2.2 in (57 mm) |

7. 1 Challenger MT800/Fendt 1100 MT/Fendt 1100 Vario MT Series vs Application Matrix (Track Width)

| CATEGORY | APPLICATION/OPERATION DESCRIPTION | 18 in and 25 in (457 mm and 648 mm) |

27 in & 30 in (699 mm and 762 mm) |

36 in (914 mm) |

|---|---|---|---|---|

| Field Conditions | Minimal ground disturbance/Berming | Not recommended | OK to use | OK to use |

| Extreme cold | Not recommended | OK to use | OK to use | |

| In furrow applications | OK to use | Not recommended | Not recommended | |

| Short fields, applications requiring a lot of turning | OK to use | OK to use | OK to use | |

| Flat land farming, slopes up to 10% | OK to use | OK to use | OK to use | |

| Moderate side slope applications, slopes from 10 to 25% | OK to use | OK to use | OK to use | |

| Severe side slope applications, slopes greater than 25% | Not recommended | OK to use | OK to use | |

| Road Travel | Small amount of roading, most field and travel distances within 5 mile radius | OK to use | OK to use | OK to use |

| Moderate amount of roading, most field and travel distances between 5 and 10 mile radius | OK to use | OK to use | OK to use | |

| High amount of roading, typically travel in excess of 10 miles | Not recommended | OK to use | OK to use | |

| Applications | Primary tillage (deep ripping, chisel plow, etc.) | Not recommended | OK to use | OK to use |

| Secondary tillage (field cultivator, disk, roller, etc.) | Not recommended | OK to use | OK to use | |

| Fully mounted roll over plow | Not recommended | OK to use | OK to use | |

| Row crop planter | OK to use | OK to use | OK to use | |

| Air seeder | Not recommended | OK to use | OK to use | |

| Manure tank | Not recommended | OK to use | OK to use | |

| Grain cart | Not recommended | OK to use | OK to use | |

| Tile plow | Not recommended | OK to use | OK to use | |

| Spraying | OK to use | OK to use | OK to use | |

| Haybaling | Not recommended | OK to use | OK to use | |

| Stalk chopper/Brush Hog | OK to use | OK to use | OK to use | |

| Vegetable bedder | OK to use | OK to use | OK to use | |

| Front blade - Silage | Not recommended | OK to use | OK to use | |

| Forage harvestor | OK to use | OK to use | OK to use | |

| Snow grooming | Not recommended | OK to use | OK to use | |

| Agricultural scraper | Not recommended | OK to use | OK to use | |

| Commercial scraper | Not recommended | OK to use | OK to use | |

| Forestry | Not recommended | OK to use | OK to use | |

| Non-agricultural applications | Not recommended | OK to use | OK to use |

7. 2 Challenger MT800/Fendt 1100 MT/Fendt 1100 Vario MT Series Track Cross Reference (Current Tracks)

| CURRENT AGCO P/N | CURRENT P/N | TRACK WIDTH | PREVIOUS P/N | PREVIOUS AGCO P/N |

|---|---|---|---|---|

| ACP0316970 | A27AS03296 | 27.5 in (699 mm) | - | - |

| ACP0316980 | A30AS03297 | 30 in (762 mm) | - | - |

| - | F25AS03179 | 25.5 in (648 mm) | - | - |

| 581861D1 | F27AS02998 | 27.5 in (699 mm) | 636-2718 | 563765D1 |

| 581864D1 | F30AS03001 | 30 in (762 mm) | 636-3063 | 563766D1 |

| 581868D1 | F36AS03003 | 36 in (914 mm) | 636-3653 | 563767D1 |

| - | F27AS02931 | 27.5 in (699 mm) | - | - |

| - | F30AS02933 | 30 in (762 mm) | - | - |

| 581860D1 | E18AS02930 | 18 in (457 mm) | 656-1836 | 554110D1 |

| 581862D1 | E27AS02997 | 27.5 in (699 mm) | 656-2716 | 554101D1 |

| 581866D1 | E30AS03000 | 30 in (762 mm) | 656-3058 | 554102D1 |

| 581870D1 | E36AS03002 | 36 in (914 mm) | 656-3648 | 554103D1 |

| - | E25AS03180 | 25.5 in (648 mm) | - | - |

| 581863D1 | E27AS02996 | 27.5 in (699 mm) | 656-2717 | 554113D1 |

| 581867D1 | E30AS02999 | 30 in (762 mm) | 656-3059 | 554112D1 |

| 581865D1 | E30AS02932 | 30 in (762 mm) | 696-3066 | 554096D1 |

| 581869D1 | E36AS02934 | 36 in (914 mm) | 696-3651 | 554097D1 |

7. 3 Challenger MT800/Fendt 1100 MT/Fendt 1100 Vario MT Series Track Cross Reference (Older Tracks)

| PREVIOUS P/N | WIDTH | PREVIOUS AGCO P/N |

|---|---|---|

| 656-1816 656-1836 |

18 in | 1R-1388 508608D1 554110D1 |

| 636-2708 636-2718 |

27 in | 1R-1265 554089D1 |

| 656-2707 656-2716 |

27 in | 1R-1323 508597D1 554101D1 |

| 656-2710 656-2717 |

27 in | 519314D1 554113D1 |

| 636-3029 636-3063 |

30 in | 1R-1266 554090D1 |

| 656-3031 656-3058 |

30 in | 1R-1325 508598D1 554102D1 |

| 696-3017 696-3056 696-3066 |

30 in | 501186D1 554096D1 |

| 656-3045 656-3059 |

30 in | 518709D1 554112D1 |

| 636-3621 636-3653 |

36 in | 1R-1267 554091D1 |

| 656-3622 656-3648 |

36 in | 1R-1360 508599D1 554103D1 |

| 696-3605 696-3644 696-3651 |

36 in | 501196D1 554097D1 |

8. FENDT IDEAL COMBINE TRACK SELECTION

- Produced from 2018 to current

- 450 to 650 HP

- 298 in (7560 mm) track length

- Positive Drive Track System

- Models Affected: Ideal 7T, Ideal 8T, Ideal 9T, Ideal 10T

| AGCO P/N | P/N | TRACK WIDTH | TREADS QTY | TREAD BAR HEIGHT | TREAD BAR TIP WIDTH | TREAD BAR PITCH | DRIVE LUGS QTY | DRIVE LUG PITCH | CARCASS THICKNESS | PLY LAYERS |

|---|---|---|---|---|---|---|---|---|---|---|

| ACW1076360 | B26BX03129 | 26 in (660 mm) | 100 | 2.6 in (66 mm) | 1.7 in (44 mm) | 6 in (153 mm) | 50 | 6 in (153 mm) | 1.4 in (35 mm) | 3 |

| ACW1743300 | B30BX03260 | 30 in (762 mm) | 100 | 2.6 in (66 mm) | 1.7 in (44 mm) | 6 in (153 mm) | 50 | 6 in (153 mm) | 1.4 in (35 mm) | 3 |

| ACW1076380 | B36BX03133 | 36 in (914 mm) | 100 | 2.6 in (66 mm) | 1.7 in (44 mm) | 6 in (153 mm) | 50 | 6 in (153 mm) | 1.4 in (35 mm) | 3 |

| ACW1076390 | B36BX03135 | 36 in (914 mm) | 70 | 3 in (75 mm) | 2.5 in (64 mm) | 8.6 in (218 mm) | 50 | 6 in (153 mm) | 1.4 in (35 mm) | 3 |

9. MASSEY FERGUSON IDEAL COMBINE TRACK SELECTION

General Facts

- Produced from 2018 to current

- 450 to 650 HP

- 298 in (7560 mm) track length

- Positive Drive Track System

- Models Affected: Ideal 7T, Ideal 8T, Ideal 9T, Ideal 10T

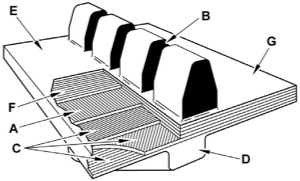

Our positive drive tracks are constructed using natural and synthetic rubber in combination with steel reinforcing layers and main cables. The continuous wound main cables give the track tensile strength to carry the main load and resist breakage. The bias alignment plys aid in track alignment and the reinforcing plies protect the main cables. The treadbars are designed to provide roading wear life, resistance to wear in the field, and provide optimum traction for varied conditions and applications. The drive lugs are designed to engage the drive bars on the drive wheel to transfer the loads of traction and braking, and to ensure engagement of the track between the idler and midrollers.

| AGCO P/N | P/N | TRACK WIDTH | TREADS QTY | TREAD BAR HEIGHT | TREAD BAR TIP WIDTH | TREAD BAR PITCH | DRIVE LUGS QTY | DRIVE LUG PITCH | CARCASS THICKNESS | PLY LAYERS |

|---|---|---|---|---|---|---|---|---|---|---|

| ACW1076360 | B26BX03129 | 26 in (660 mm) | 100 | 2.6 in (66 mm) | 1.7 in (44 mm) | 6 in (153 mm) | 50 | 6 in (153 mm) | 1.4 in (35 mm) | 3 |

| ACW1743300 | B30BX03260 | 30 in (762 mm) | 100 | 2.6 in (66 mm) | 1.7 in (44 mm) | 6 in (153 mm) | 50 | 6 in (153 mm) | 1.4 in (35 mm) | 3 |

| ACW1076380 | B36BX03133 | 36 in (914 mm) | 100 | 2.6 in (66 mm) | 1.7 in (44 mm) | 6 in (153 mm) | 50 | 6 in (153 mm) | 1.4 in (35 mm) | 3 |

| ACW1076390 | B36BX03135 | 36 in (914 mm) | 70 | 3 in (75 mm) | 2.5 in (64 mm) | 8.6 in (218 mm) | 50 | 6 in (153 mm) | 1.4 in (35 mm) | 3 |

10. BOLT-ON REPLACEMENT GUIDE LUGS

- Used to replace missing or worn guide lugs on tracks with greater than 50% of tread life remaining.

- Guide lug design distributes forces across the entire length of the guide lug improving replacement guide lug durability and retainability.

- The retaining plate is designed to prevent damage to the guide lug when high stresses are applied to the guide lug.

- Guide lug material is the same material as the guide lugs on new tracks providing consistent wear.

- Bolt-on guide lugs can be an economical way to increase the life of tracks in certain conditions.

| P/N | AGCO P/N | MACHINE | DESCRIPTION |

|---|---|---|---|

| GLO7088 | 79035298 | MT700 900 Vario MT |

Challenger MT700 Bolt On Guide Lug Kit |

| GLO7089 | 79035299 | MT800 1100 MT 1100 Vario MT |

Challenger MT800 Bolt On Guide Lug Kit |

11. MT700/MT800 & 900 VARIO MT/1100 MT/1100 VARIO MT WHEEL SELECTION & USAGE

11.1 Challenger MT700/Fendt 900 Vario MT

11.2 Challenger MT800/Fendt 1100 MT/ Fendt 1100 Vario MT Series

11.3 Compatibility Matrix Idler Wheel

| TRACK WIDTH | IDLER WHEEL WIDTH | ||

|---|---|---|---|

| Narrow 4 in (102 mm) |

Medium 5 in (127 mm) |

Wide 8.4 in (213 mm) |

|

| 14 in (356 mm) | Recommended | Not Compatible | Not compatible |

| 16 in (406 mm) | OK to use | Recommended | Not compatible |

| 18 in (457 mm) | OK to use | Recommended | Not compatible |

| 20 in (508 mm) | OK to use | Recommended | Not compatible |

| 24 in (610 mm) | Not recommended | Recommended | Not compatible |

| 25 in (635 mm) | Not compatible | Recommended | Not recommended |

| 27.5 in (699 mm) | Not compatible | Not recommended | Recommended |

| 30 in (762 mm) | Not compatible | Not recommended | Recommended |

| 34 in (864 mm) | Not compatible | Not compatible | Recommended |

| 36 in (914 mm) | Not compatible | Not compatible | Recommended |

11.4 Compatibility Matrix Midroller

| TRACK WIDTH | MIDROLLER WIDTH | ||

|---|---|---|---|

| Narrow 4.3 in (109 mm) |

Medium 5.2 in (132 mm) |

Wide 8.8 in (224 mm) |

|

| 14 in (356 mm) | Recommended | OK to use | Not compatible |

| 16 in (406 mm) | OK to use | Recommended | Not compatible |

| 18 in (457 mm) | Not recommended | Recommended | Not compatible |

| 20 in (508 mm) | Not recommended | Recommended | Not compatible |

| 24 in (610 mm) | Not recommended | Recommended | Not recommended |

| 25 in (635 mm) MT700/900 Vario MT | Not compatible | Not recommended | Recommended |

| 25 in (635 mm) MT800/1100 MT | Not compatible | Recommended | Not compatible |

| 27.5 in (699 mm) | Not compatible | Not compatible | Recommended |

| 30 in (762 mm) | Not compatible | Not compatible | Recommended |

| 34 in (864 mm) | Not compatible | Not compatible | Recommended |

| 36 in (914 mm) | Not compatible | Not compatible | Recommended |

11.5 Compatibility Matrix Drive Wheel

| TRACK WIDTH | DRIVE WHEEL WIDTH | ||

|---|---|---|---|

| Narrow 4.5 in (115 mm) |

Medium 5.5 in (140 mm) |

Wide 8.8 in (224 mm) |

|

| 14 in (356 mm) | Recommended | OK to use | Not compatible |

| 16 in (406 mm) | OK to use | Recommended | Not compatible |

| 18 in (457 mm) | Not recommended | Recommended | Not compatible |

| 20 in (508 mm) | Not recommended | Recommended | Not compatible |

| 24 in (610 mm) | Not recommended | Recommended | Not recommended |

| 25 in (635 mm) MT700/900 Vario MT | Not compatible | Not recommended | Recommended |

| 25 in (635 mm) T800/1100 MT | Not compatible | Recommended | Not compatible |

| 27.5 in (699 mm) | Not compatible | Not compatible | Recommended |

| 30 in (762 mm) | Not compatible | Not compatible | Recommended |

| 34 in (864 mm) | Not compatible | Not compatible | Recommended |

| 36 in (914 mm) | Not compatible | Not compatible | Recommended |

12. CHALLENGER MT700/MT800 WHEEL REPLACEMENT CRITERIA

12.1 Idler Wheel

- Rubber material is worn or missing

- Steel hub is cracked or damaged

| DESCRIPTION | ORIGINAL PARTS | REMANUFACTURED PARTS | ||

|---|---|---|---|---|

| P/N | AGCO P/N | P/N | AGCO P/N | |

| Narrow Idler | 5W-0051PA | 504781D1 | 5W-0051RPA | 504781D1R |

| Medium Idler (MT700 Only) | 5W-0032PA | 504782D1 | 5W-0032RPA | 504782D1R |

| Medium Idler (MT800 Only) | 5W-0047PA | 504783D1 | 5W-0047RPA | 504783D1R |

| Wide Idler | 5W-0330PA | 504784D2 | 5W-0330RPA | 504784D2R |

12.2 Midroller

Midrollers carry most of the weight for the tractor.

Midrollers will wear over time and are susceptible to heat buildup from roading, track misalignment, and side hill applications. In most applications, rubber midrollers will provide adequate life. In harsh applications, poly midrollers may improve life of the midroller and should be used.

Midrollers should be replaced if:

- Rubber/Poly material is missing/worn all the way across the width of the midroller.

- 1/3 of the rubber/poly material is missing/worn all the way around the midroller.

- Rubber/poly material is worn thin enough that material is sticking to the midroller.

- Steel hub is cracked or damaged

- Midroller is no longer round (flat spot worn into surface)

| DESCRIPTION | ORIGINAL PARTS | REMANUFACTURED PARTS | ||

|---|---|---|---|---|

| P/N | AGCO P/N | P/N | AGCO P/N | |

| Narrow Midroller (rubber, MT700 Only) | 502930D1 | 502930D1 | - | - |

| Medium Midroller (rubber) | 502932D1 | 502931D1 | - | - |

| Wide Midroller (rubber) | 502932D1 | 502932D | - | - |

| Medium Midroller (poly) | 548349D3 | 521194D1 548349D3 | 4W-5052 | 548349D3R |

| Wide Midroller (poly) | 548350D3 | 521195D1 548350D3 | 4W-5050 | 548350D3R |

12.3 Drive Wheel

Drive wheels provide the friction drive to the inside surface of the track to transfer the engine power to the ground. The friction surface is determined by the depth and sharpness of the chevrons cut into the drive wheel surface.

Drive wheels should be replaced if:

- Rubber material is missing or worn resulting in excessive drive wheel to track slippage.

- Steel hub is cracked or damaged

| DESCRIPTION | ORIGINAL PARTS | REMANUFACTURED PARTS | ||

|---|---|---|---|---|

| P/N | AGCO P/N | P/N | AGCO P/N | |

| Narrow Drive Wheel (RH) (MT700 Only) | 3W-0057PA | 504785D1 | 504785D1RPA | 504785D1R |

| Narrow Drive Wheel (LH) (MT700 Only) | 3W-0060PA | 504786D1 | 504786D1RPA | 504786D1R |

| Medium Drive Wheel (RH) | 3W-0064PA | 504787D1 | 504787D1RPA | 504787D1R |

| Medium Drive Wheel (LH) | 3W-0067PA | 504788D1 | 504788D1RPA | 504788D1R |

| Wide Drive Wheel (RH) | 3W-0071PA | 504789D1 | 504789D1RPA | 504789D1R |

| Wide Drive Wheel (LH) | 3W-0074PA | 504790D1 | 504790D1RPA | 504790D1R |

13. FENDT 900 VARIO MT/1100 MT/ 1100 VARIO MT WHEEL REPLACEMENT CRITERIA

13.1 Idler Wheel

The idler wheels are the front wheels. The idler wheels are attached to the track tensioning system and provide the tension on the track. They also aid in adjustment of track alignment.

Idler Wheels should be replaced if:

- Rubber material is worn or missing

- Steel hub is cracked or damaged

| DESCRIPTION | ORIGINAL PARTS | |

|---|---|---|

| P/N | AGCO P/N | |

| Narrow Idler (900 Vario MT only) | 5W-0431PA | ACW3341620 |

| Medium Idler (900 Vario MT Only) | 5W-0433PA | ACW3341630 |

| Medium Idler (1100 MT Only) | 5W-0437PA | ACW3215580 |

| Wide Idler | 5W-0435PA | ACW3215590 |

13.2 Midroller

Midrollers carry most of the weight for the tractor.

Midrollers will wear over time and are susceptible to heat buildup from roading, track misalignment, and side hill applications. In most applications, rubber midrollers will provide adequate life. In harsh applications, poly midrollers may improve life of the midroller and should be used.

Midrollers should be replaced if:

- Rubber/Poly material is missing/worn all the way across the width of the midroller.

- 1/3 of the rubber/poly material is missing/worn all the way around the midroller.

- Rubber/poly material is worn thin enough that material is sticking to the midroller.

- Steel hub is cracked or damaged

- Midroller is no longer round (flat spot worn into surface)

| DESCRIPTION | ORIGINAL PARTS | REMANUFACTURED PARTS | ||

|---|---|---|---|---|

| P/N | AGCO P/N | P/N | AGCO P/N | |

| Medium Midroller (rubber) | 4W-0024PA | 502931D1 | - | - |

| Wide Midroller (rubber) | 4W-0020PA | 502932D1 | - | - |

| Medium Midroller (poly) | 4W-5007PA | 548349D3 | 548349D3RPA | 548349D3R |

| Wide Midroller (poly) | 4W-5009PA | 548350D3 | 548350D3RPA | 548350D3R |

13.3 Drive Wheel

Drive wheels provide the friction drive to the inside surface of the track to transfer the engine power to the ground. The friction surface is determined by the depth and sharpness of the chevrons cut into the drive wheel surface.

Drive wheels should be replaced if:

- Rubber material is missing or worn resulting in excessive drive wheel to track slippage.

- Steel hub is cracked or damaged

| DESCRIPTION | ORIGINAL PARTS | |

|---|---|---|

| P/N | AGCO P/N | |

| Narrow Drive Wheel (RH) (900 Vario MT Only) | 3W-0393PA | ACW333750 |

| Narrow Drive Wheel (LH) (900 Vario MT Only) | 3W-0394PA | ACW3337510 |

| Medium Drive Wheel (RH) | 3W-0389PA | ACW3210460 |

| Medium Drive Wheel (LH) | 3W-0390PA | ACW3210480 |

| Wide Drive Wheel (RH) | 3W-0391PA | ACW3210490 |

| Wide Drive Wheel (LH) | 3W-0392PA | ACW3210500 |

14. APPROXIMATE GROUND PRESSURE

| MODEL | TRACK SIZE (in) |

FLAT PLATE AREA PER TRACK (in2) |

APPROX TRACTOR WEIGHT | |||

|---|---|---|---|---|---|---|

| 24000 lbs (psi) | 31000 lbs (psi) | 36000 lbs (psi) | 45000 lbs (psi) | |||

| MT700 (A thru E Series) |

14 | 1316 | 9.1 | 11.8 | 13.7 | 17.1 |

| 16 | 1504 | 8 | 10.3 | 12 | 15 | |

| 18 | 1692 | 7.1 | 9.2 | 10.6 | 13.3 | |

| 20 | 1880 | 6.4 | 8.2 | 9.6 | 12 | |

| 25 | 2350 | 5.1 | 6.6 | 7.7 | 9.6 | |

| 30 | 2820 | 4.3 | 5.5 | 6.4 | 8 | |

| MT738, MT740, MT743, 938, 940, 943 Vario MT |

14 | 1414 | 8.5 | 11 | 12.7 | 15.9 |

| 16 | 1616 | 7.4 | 9.6 | 11.1 | 13.9 | |

| 18 | 1818 | 6.6 | 8.5 | 9.9 | 12.4 | |

| 20 | 2020 | 5.9 | 7.7 | 8.9 | 11.1 | |

| 25 | 2525 | 4.8 | 6.1 | 7.1 | 8.9 | |

| 30 | 3030 | 4 | 5.1 | 5.9 | 7.4 | |

| MODEL | TRACK SIZE (in) |

FLAT PLATE AREA PER TRACK (in2) |

APPROX TRACTOR WEIGHT | |||

|---|---|---|---|---|---|---|

| 38000 lbs (psi) | 50000 lbs (psi) | 56000 lbs (psi) | 60000 lbs (psi) | |||

| MT800, 1100 MT, 1100 Vario MT |

18 | 2088 | 9.1 | 12 | 13.4 | 14.4 |

| 27.5 | 3190 | 6 | 7.8 | 8.8 | 9.4 | |

| 30 | 3480 | 5.5 | 7.2 | 8 | 8.6 | |

| 36 | 4176 | 4.5 | 6 | 6.7 | 7.2 | |