How to Measure and Identify Rubber Tracks: Finding the Perfect Fit for Your Equipment

Table of Contents

I. Introduction

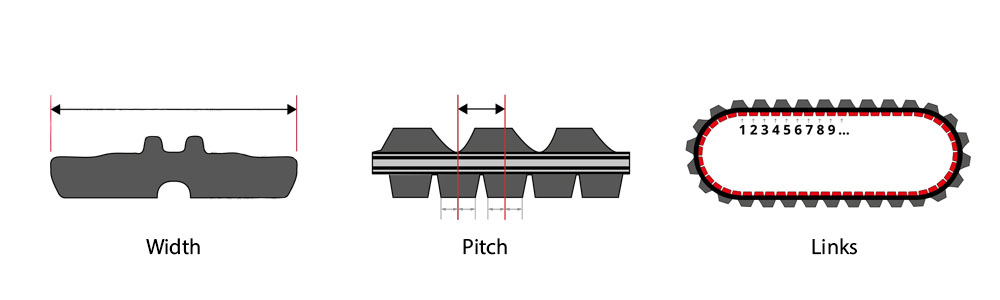

II. Understanding Key Rubber Track Measurements

- Width: This is the overall width of the track, measured from one outer edge to the other.

- Pitch: This is the distance between the centers of two consecutive drive lugs (the metal teeth that engage with the sprocket). In some cases, it might refer to the distance between guide lugs or metal links.

- Number of Links (or Guide Lugs): This is the total number of links (or guide lugs/metal links) around the entire circumference of the track.

III. Tools You'll Need

- Measuring Tape: A long, preferably steel, tape measure is essential for measuring the width and pitch.

- Pen and Paper: To record your measurements accurately.

- (Optional) Caliper: A caliper can provide more precise pitch measurements, although a tape measure is usually sufficient.

IV. A Guide to Measuring Your Tracks

Now, let’s dive into the measuring process:

A. Measuring the Track Width:

- Using your measuring tape, measure the overall width of the track from one outer edge to the other.

- Ensure the tape measure is held straight and taut for an accurate reading.

- Record the measurement in millimeters (mm) or inches.

B. Measuring the Pitch:

- Locate the drive lugs (or guide lugs/metal links) on your track.

- Using your measuring tape, measure the distance from the center of one drive lug to the center of the next drive lug. If measuring guide lugs or metal links, measure from center to center of consecutive lugs/links.

- For greater accuracy, measure multiple pitches and calculate the average.

- Record the measurement in millimeters (mm).

C. Counting the Number of Links:

- Mark your starting point on the track with a pen or marker.

- Carefully count each link (or guide lug/metal link) around the entire circumference of the track.

- Continue counting until you reach your starting point.

- Record the total number of links.

V. Using the Original Part Number for Verification

Knowing the original track’s part number or product code can be extremely helpful in ensuring you get the correct replacement. This number is often:

- Stamped directly onto the inside or outside of the rubber track itself.

- Found in your equipment’s operator’s manual.

- Located on a sticker or plate attached to the undercarriage of your machine.

If you can find this part number, provide it to Nissitrac along with your measurements. Our experts can use this information to verify the exact track size and specifications, ensuring a perfect match for your equipment.

Part Number Reference List (Partial) for Heavy-Duty Agricultural Machinery Rubber Tracks

To further assist you in identifying the correct tracks, here are some common part numbers for agricultural rubber tracks for your information:

| Brands | Models | TRACK WIDTH (in) | REPLACE PART NUMBER | OEM PART NUMBER |

|---|---|---|---|---|

| AGCO | MT700 | 14 | E14AR02908 | 581838D1 |

| AGCO | MT700 | 14 | E14AR02909 | 581839D1 |

| AGCO | MT700 | 16 | E16AR02919 | 581844D1 |

| AGCO | MT700 | 16 | E16AR02920 | 581845D1 |

| AGCO | MT700 | 16 | F16AR02921 | 581842D1 |

| AGCO | MT700 | 16 | F16AR02922 | 581843D1 |

| AGCO | MT700 | 18 | E18AR02923 | 581848D1 |

| AGCO | MT700 | 18 | F18AR02926 | 581846D1 |

| AGCO | MT700 | 18 | F18AR02927 | 581847D1 |

| AGCO | MT700 | 25 | E25AR02989 | 581854D1 |

| AGCO | MT700 | 25 | E25AR02990 | 581853D1 |

| AGCO | MT700 | 25 | F25AR02991 | 581851D1 |

| AGCO | MT700 | 25 | F25AR02992 | 581852D1 |

| AGCO | MT700 | 30 | E30AR02993 | 581857D1 |

| AGCO | MT700 | 30 | E30AR02994 | 581856D1 |

| AGCO | MT700 | 30 | E30AR02995 | 581855D1 |

| AGCO | MT800 | 18 | E18AS02930 | 581860D1 |

| AGCO | MT800 | 27.5 | E27AS02996 | 581863D1 |

| AGCO | MT800 | 27.5 | E27AS02997 | 581862D1 |

| AGCO | MT800 | 27.5 | F27AS02998 | 581861D1 |

| AGCO | MT800 | 30 | E30AS02932 | 581865D1 |

| AGCO | MT800 | 30 | E30AS02999 | 581867D1 |

| AGCO | MT800 | 30 | E30AS03000 | 581866D1 |

| AGCO | MT800 | 30 | F30AS03001 | 581864D1 |

| AGCO | MT800 | 36 | E36AS03002 | 581870D1 |

| AGCO | MT800 | 36 | E36AS02934 | 581869D1 |

| AGCO | MT800 | 36 | F36AS03003 | 581868D1 |

| AGCO | MT700 A to E | 34 | E34AR03102 | 581859D1 |

| AGCO | MT700 A to E | 34 | F34AR03101 | 581858D1 |

| AGCO | MT738, 740, 743 | 14 | E14BY03116 | 588707D1 |

| AGCO | MT738, 740, 743 | 14 | E14BY03117 | 588708D1 |

| AGCO | MT738, 740, 743 | 16 | E16BY03201 | 588713D1 |

| AGCO | MT738, 740, 743 | 16 | E16BY03202 | 588714D1 |

| AGCO | MT738, 740, 743 | 18 | E18BY03203 | 588717D1 |

| AGCO | MT738, 740, 743 | 25 | E25BY03115 | 588721D1 |

| AGCO | MT738, 740, 743 | 25 | E25BY03204 | 588722D1 |

| AGCO | MT738, 740, 743 | 30 | E30BY03205 | 588724D1 |

| AGCO | MT738, 740, 743 | 30 | E30BY03206 | 588725D1 |

| AGCO | MT738, 740, 743 | 34 | E34BY03207 | 588727D1 |

| AGCO | MT738, 740, 743 | 16 | F16BY03127 | 588709D1 |

| AGCO | MT738, 740, 743 | 16 | F16BY03128 | 588710D1 |

| AGCO | MT738, 740, 743 | 18 | F18BY03229 | 588715D1 |

| AGCO | MT738, 740, 743 | 18 | F18BY03230 | 588716D1 |

| AGCO | MT738, 740, 743 | 25 | F25BY03114 | 588622D1 |

| AGCO | MT738, 740, 743 | 25 | F25BY03233 | 588720D1 |

| AGCO | MT738, 740, 743 | 30 | F30BY03234 | 588723D1 |

| AGCO | MT738, 740, 743 | 34 | F34BY03235 | 588726D1 |

| Case IH | Quadtrac | 30 | E30BE02858 | 84606975 |

| Case IH | Quadtrac | 30 | E30BE02837 | 84606977 |

| Case IH | Quadtrac | 30 | 634-3023 | 84182440 |

| Case IH | Quadtrac | 36 | E36BE02857 | 84606976 |

| Case IH | Quadtrac | 36 | 634-3616 | 84214145 |

| Case IH | Quadtrac | 40 | 634-3026 | 84341573 |

| Case IH | 9300 | 30 | 654-3025 | 84341571 |

| Case IH | Rowtrac MY19 | 16 | F16BG03401 | 51417218 |

| Case IH | Rowtrac MY19 | 18 | F18BG03374 | 51417219 |

| Case IH | Rowtrac MY19 | 21 | F21BG03413 | 51444172 |

| Case IH | Rowtrac MY19 | 24 | F24BG03397 | 51417221 |

| Case IH | Rowtrac MY19 | 30 | F30BG03402 | 51417222 |

| Fendt | 900 MT Vario | 16 | F16BY03127 | 588709D1 |

| Fendt | 900 MT Vario | 16 | F16BY03128 | 588710D1 |

| Fendt | 900 MT Vario | 18 | F18BY03229 | 588715D1 |

| Fendt | 900 MT Vario | 18 | F18BY03230 | 588716D1 |

| Fendt | 900 MT Vario | 25 | F25BY03114 | 588622D1 |

| Fendt | 900 MT Vario | 25 | F25BY03233 | 588720D1 |

| Fendt | 900 MT Vario | 30 | F30BY03234 | 588723D1 |

| Fendt | 900 MT Vario | 34 | F34BY03235 | 588726D1 |

| Fendt | 900 MT Vario | 14 | E14BY03116 | 588707D1 |

| Fendt | 900 MT Vario | 14 | E14BY03117 | 588708D1 |

| Fendt | 900 MT Vario | 16 | E16BY03201 | 588713D1 |

| Fendt | 900 MT Vario | 16 | E16BY03202 | 588714D1 |

| Fendt | 900 MT Vario | 18 | E18BY03203 | 588717D1 |

| Fendt | 900 MT Vario | 25 | E25BY03115 | 588721D1 |

| Fendt | 900 MT Vario | 25 | E25BY03204 | 588722D1 |

| Fendt | 900 MT Vario | 30 | E30BY03205 | 588724D1 |

| Fendt | 900 MT Vario | 30 | E30BY03206 | 588725D1 |

| Fendt | 900 MT Vario | 34 | E34BY03207 | 588727D1 |

| Fendt | 900 MT Vario | 27.5 | F27AS02998 | 581861D1 |

| Fendt | 900 MT Vario | 30 | F30AS03001 | 581864D1 |

| Fendt | 1100 MT Vario | 36 | F36AS03003 | 581868D1 |

| Fendt | 1100 MT Vario | 18 | E18AS02930 | 581860D1 |

| Fendt | 1100 MT Vario | 27.5 | E27AS02997 | 581862D1 |

| Fendt | 1100 MT Vario | 27.5 | E27AS02996 | 581863D1 |

| Fendt | 1100 MT Vario | 30 | E30AS03000 | 581866D1 |

| Fendt | 1100 MT Vario | 30 | E30AS02999 | 581867D1 |

| Fendt | 1100 MT Vario | 30 | E30AS02932 | 581865D1 |

| Fendt | 1100 MT Vario | 36 | E36AS03002 | 581870D1 |

| Fendt | 1100 MT Vario | 36 | E36AS03002 | 581869D1 |

| Fendt | IDEAL | 26 | B26BX03129 | ACW1076360 |

| Fendt | IDEAL | 30 | B30BX03260 | ACW1743300 |

| Fendt | IDEAL | 36 | B36BX03133 | ACW1076380 |

| Fendt | IDEAL | 36 | B36BX03135 | ACW1076390 |

| John Deere | 8000T | 16 | 651-1604 | R222974 |

| John Deere | 8000T | 16 | 651-1605 | R222975 |

| John Deere | 8000T | 18 | 631-1608 | R241742 |

| John Deere | 8000T | 18 | 651-1804 | R222976 |

| John Deere | 8000T | 18 | 651-1823 | R312148 |

| John Deere | 8000T | 18 | 651-1824 | R312149 |

| John Deere | 8000T | 18 | 631-1803 | R241743 |

| John Deere | 8000T | 25 | 651-2504 | R241750 |

| John Deere | 8000T | 25 | F25AT01942 | R545939 |

| John Deere | 8000T | 25 | 631-2509 | R241745 |

| John Deere | 8000T | 25 | 631-2503 | R220829 |

| John Deere | 8000T | 30 | 651-3039 | R292531 |

| John Deere | 8000T | 30 | F30AT02943 | R545938 |

| John Deere | 8000T | 30 | 631-3040 | R292528 |

| John Deere | 8000T | 30 | 631-3038 | R292526 |

| John Deere | 8RT | 16 | E16AY03237 | R563760 |

| John Deere | 8RT | 16 | E16AY02944 | R545855 |

| John Deere | 8RT | 16 | E16AY02945 | R545854 |

| John Deere | 8RT | 16 | E16AY02946 | R545853 |

| John Deere | 8RT | 16 | F16AY02947 | R545852 |

| John Deere | 8RT | 18 | E18AY02948 | R545859 |

| John Deere | 8RT | 18 | E18AY02949 | R545857 |

| John Deere | 8RT | 18 | E18AY02950 | R545858 |

| John Deere | 8RT | 18 | F18AY02951 | R545856 |

| John Deere | 8RT | 24 | F24AY03010 | R545860 |

| John Deere | 8RT | 25 | E25AY03011 | R545862 |

| John Deere | 8RT | 25 | F25AY02952 | R545865 |

| John Deere | 8RT | 25 | F25AY03012 | R545861 |

| John Deere | 8RT | 30 | E30AY03013 | R545864 |

| John Deere | 8RT | 30 | F30AY02953 | R545866 |

| John Deere | 8RT | 30 | F30AY03014 | R545863 |

| John Deere | 9000T | 30 | 653-3010 | R241748 |

| John Deere | 9000T | 30 | 633-3019 | R257977 |

| John Deere | 9000T | 36 | 653-3601 | R241749 |

| John Deere | 9000T | 36 | 633-3606 | R257978 |

| John Deere | 9030T/9RT | 30 | E30AV02954 | R545869 |

| John Deere | 9030T/9RT | 30 | E30AV03019 | R545868 |

| John Deere | 9030T/9RT | 30 | F30AV02955 | R545872 |

| John Deere | 9030T/9RT | 30 | F30AV03020 | R545867 |

| John Deere | 9030T/9RT | 36 | E36AV03021 | R545871 |

| John Deere | 9030T/9RT | 36 | F36AV03022 | R545870 |

| John Deere | 9RX | 30 | B30BH03053 | R550588 |

| John Deere | 9RX | 30 | E30BH02877 | R554229 |

| John Deere | 9RX | 30 | E30BH03054 | R550589 |

| John Deere | 9RX | 36 | B36BH03047 | R550228 |

| John Deere | 9RX | 36 | E36BH02897 | R554230 |

| John Deere | 9RX Narrow | 18 | E18BT03106 | R565017 |

| John Deere | 9RX Narrow | 24 | E24BT03107 | R565018 |

| John Deere | 8RX | 18 | F18CD03570 | R571655 |

| John Deere | 8RX | 24 | F24CD03574 | R571656 |

| John Deere | 8RX | 18 | F18CA03569 | R571658 |

| John Deere | 8RX | 24 | F24CA03573 | R571659 |

| John Deere | 8RX | 30 | F30CA03717 | TR129219 |

Note: This is just a partial list. Nissitrac offers a wide range of tracks and accessories for various makes and models. Please contact us with your specific requirements, and our team will be happy to assist you.

VI. Tips for Accuracy

- Measure Multiple Times: To minimize errors, take each measurement (width, pitch, and number of links) at least two or three times and use the average value.

- Measure on a Flat Surface: If you’re measuring a track that’s been removed from the machine, lay it on a flat, level surface to ensure accurate readings.

- Worn Tracks: Keep in mind that heavily worn tracks can stretch or distort slightly over time. Therefore, measurements taken from a worn track might differ slightly from those of a new track.

VII. Identifying Your Track Size Using the Measurements and Part Number

Once you have your measurements, you can typically identify the track size using the following format:

Width (mm) x Pitch (mm) x Number of Links

For example, a track might be identified as 762 x 152.4 x 45, meaning it has a width of 762mm, a pitch of 152.4mm, and 45 links.

When you provide your measurements and the original part number (if available) to Nissitrac, our team can confirm the correct track size for your machine. We can also help you navigate any variations or special considerations based on your equipment and application.

You can also check out our helpful track size for a quick reference.

VIII. Matching Tread Pattern and Application to Your Needs

A. Understanding Tread Patterns

- Block Pattern: Versatile pattern suitable for general use, offering good traction and durability.

- C-Lug Pattern: Provides excellent traction in softer ground conditions, such as mud or clay.

- Multi-Bar Pattern: A good all-around choice for agricultural applications, offering a balance of traction and flotation.

- Z-Lug Pattern: Common for construction equipment and designed for hard surfaces.

- Rice and Cane Pattern: Specifically designed for rice and cane fields, designed to work in extremely wet and muddy conditions.

- Turf Pattern: Designed to minimize ground disturbance on sensitive surfaces like lawns and golf courses.

B. Considering Your Application:

Think about the primary environment and tasks your equipment will be performing.

|

Application |

Recommended Tread Patterns |

|

General Agriculture |

Block, Multi-Bar, C-Lug |

|

Muddy Conditions |

Wide-spaced, aggressive patterns (e.g., Rice and Cane) |

|

Turf/Landscaping |

Turf-friendly, minimal ground disturbance patterns |

|

Construction |

Block, Z-Lug |

C. Nissitrac Recommendations:

The experts at Nissitrac can provide personalized recommendations based on your specific machine, application, and typical terrain. We’ll help you choose the optimal tread pattern to maximize performance and minimize wear and tear.

IX. Other Factors to Consider When Choosing Rubber Tracks

- A. Machine Make and Model: Always ensure the tracks you choose are compatible with your equipment’s specific make and model.

- B. Quality: Investing in high-quality rubber tracks from a reputable supplier like Nissitrac ensures durability, longevity, and optimal performance. Our tracks are built to withstand demanding conditions and provide excellent value for your investment.

X. Conclusion

Measuring and identifying the correct rubber tracks for your equipment is essential for ensuring its longevity and performance. By following this comprehensive guide and providing your measurements, original part number (if available), machine make and model, and application details to Nissitrac, you can be confident in selecting the perfect tracks for your needs.

Ready to find your perfect fit? Visit our website to browse our wide selection of high-quality rubber tracks for various agricultural and construction equipment. Contact our expert team today for personalized assistance and recommendations. We’re here to help!