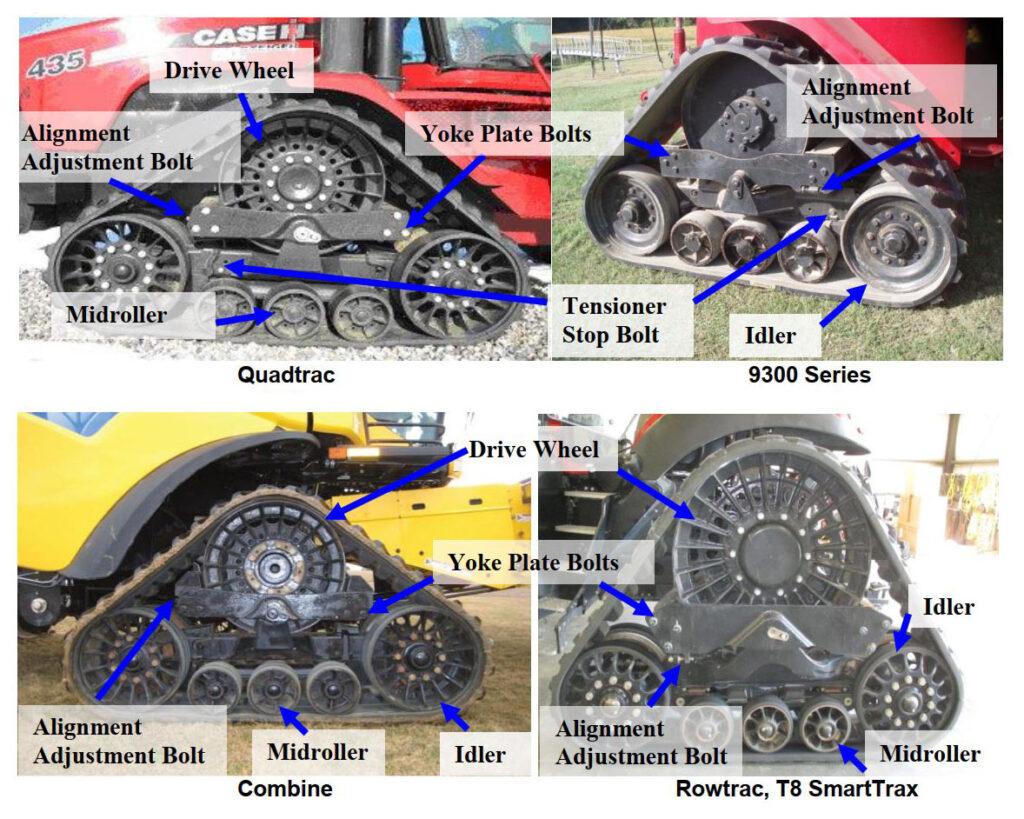

How to Replace & Maintain Case IH Rowtrac & New Holland T8 Smarttrax Rubber Tracks: A Step-by-Step Guide

Table of Contents

I. Introduction

Case IH Rowtrac and New Holland T8 Smarttrax tractors rely on their robust rubber track systems for superior traction, reduced soil compaction, and optimal performance in demanding agricultural environments. Maintaining these tracks in prime condition is essential to ensure your machine operates efficiently, minimizes downtime, and maximizes its lifespan. This comprehensive guide provides detailed, step-by-step instructions for replacing and maintaining the rubber tracks on your Case IH Rowtrac and New Holland T8 Smarttrax, helping you keep your equipment running smoothly.

II. Estimated Time for Track Replacement and Alignment

The time required for track replacement and alignment can vary depending on experience, tools, and working conditions. However, based on average skills and working on firm, level ground, you can expect the following time estimates:

- Track Removal, Inspection & Installation: 5 – 2 man-hours per track.

- Track Alignment: 0 – 1* man-hours per track.

* Note: If additional parts need to be replaced on the undercarriage as a result of a machine inspection, the total time may be significantly longer than shown.

Important Note: These are estimated times. Working in adverse conditions can take significantly longer, while experienced technicians with optimal tools may complete the work faster. Always inspect front idler pivot bushings and mounting hardware for wear or play and repair as needed before installing new track. Excessive play in front idler pivot assembly will cause track alignment problems and track damage that will not be covered by track warranty.

III. Essential Preparation for Track Maintenance

A. Safety First:

-

- Park the tractor on a level, firm surface to ensure stability.

- Disconnect any implements that might be attached.

- Turn off the engine, remove the key, and engage the parking brake.

- Engage the articulation lock.

B. Gather Your Tools:

-

- Safety Glasses and Steel Toed Shoes

- Tension Cylinder Drain Valve (CNH #31-3183)

- Pilot Pins (for idler installation)

- Ratcheting hoist / “Come Along”

- Selection of pry bars (at least one 5 ft long)

- Infrared Thermometer

- Torque Wrench (600 ft-lb / 813 Nm capacity)

- (4) 15 Ton / 15000Kg Minimum Support Stands

- 3/4″ Air Impact Wrench (with 450 ft-lb / 610 Nm capacity)

- Several large wood blocks

- (2) Lifting Eyes

- Air / Hydraulic Jack (min 15 Ton / 15000Kg Capacity / 12″ stroke)

- Soap solution (for track installation)

- 24mm and 30mm combination wrenches

- 30mm, 32mm, 34mm, and 36mm 3/4″ drive sockets

C. Understand Torque Values:

-

- Correctly torquing bolts is crucial. Refer to these values for Rowtrac and T8 Smarttrax, and always consult your operator’s manual for model-specific requirements.

- Tension cylinder stop bolt and nut (if required):170 to 190 lb ft (235 to 260 Nm)

- Steel idler wheel (early production – lubed with 10W-30 engine oil):315 to 345 lb ft (427 to 468 Nm)

- Cast idler wheel bolts (late production – lubed with 10W-30 engine oil):490 to 550 lb ft (575 to 630 Nm)

- Yoke plate bolts (lubed with 10W-30 engine oil):500 to 585 lb ft (678 to 793 Nm)

- Important Note:Wheel bolt torque is critical. Always use a torque wrench and refer to the operator’s manual for wheel bolt torques by specific model.

- Correctly torquing bolts is crucial. Refer to these values for Rowtrac and T8 Smarttrax, and always consult your operator’s manual for model-specific requirements.

IV. Step-by-Step Track Removal (ROWTRAC, T8 SMARTTRAX)

A. Detensioning the Track:

-

- To aid in track detensioning, drive the front idler wheels up on wood blocks.

- Obtain the CNH part number 31-3183 Tension Cylinder Drain Valve.

- Locate the drain port on the undercarriage, remove the dust cap, and ensure the drain valve is CLOSED.

- Attach the drain valve hose to the coupler on the undercarriage.

- Important:Track tension cylinder pressure can be 3000 psi or higher. Use caution and open the valve slowly.

- Insert the opposite end of the hose into a suitable drain bucket.

- Using a 15/16″ open-end wrench, slowly turn the valve CLOCKWISE to open it and relieve the pressure in the tensioner.

B. Raising the Machine:

-

- Raise the machine until the midrollers are approximately one (1) inch above the track.

- Important:Lifting devices with focalized contact areas, such as bottle jacks, can damage or fail the axle housings. We highly recommend you do not jack on the axle housing. Refer to your operator’s manual or contact your Case IH or New Holland dealer for recommended lifting instructions.

C. Removing Idler Wheels:

-

- Remove both front and rear outside idler wheel bolts.

- Remove both idler wheels.

D. Track Removal from Drive Wheel:

-

- With both idler wheels removed, raise the machine approximately eight inches off the ground, or until the midrollers clear the track drive lugs.

- Narrow tracks (16″ and 18″ widths) can typically be slid outwards and off of the inside idlers by hand. Wider tracks (24″ and 30″ widths) can be slid outwards by hand, or by using a strap and forklift.

- Once the bottom of the track is slid out, the track will lift out of the drive wheel pockets. Use a boom truck with a strap, a forklift with a strap, or the tines of a forklift to carefully lift the track off of the drive wheel and then outwards away from the machine.

-

- Important:Track removal requires a forklift or a boom truck, as the tracks weigh approximately 540-950 lbs, depending on width. Use caution to prevent injury.

- If the tension cylinder is still partially extended, retract it further using a come-along or other suitable means to aid in track installation later.

-

- Once the tensioner is fully retracted, close the drain valve and remove the drain valve tool.

V. Undercarriage Inspection (ROWTRAC, T8 SMARTTRAX)

A. Front Idler Pivot and Drive Wheel Inspection:

-

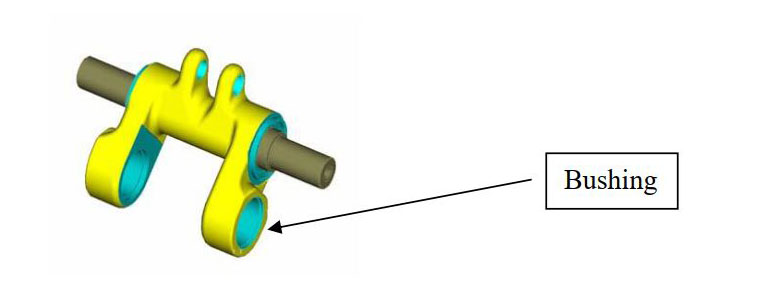

- Check for wear or play in the front idler pivot assembly and bearings.

- Any side-to-side movement indicates wear, and bushings should be inspected/replaced.

- Excessive play will cause track alignment problems and rapid drive lug wear.

- Ensure front idler pivot pin bolts are torqued to 424-465 ft-lb (575-630 Nm).

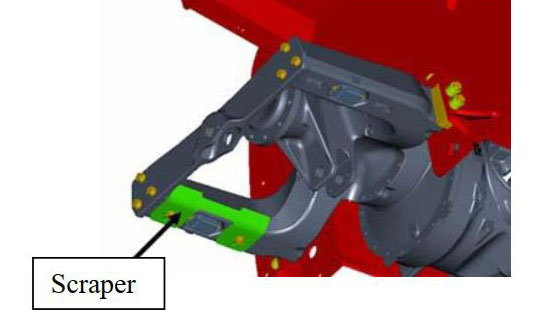

- Ensure the drive wheel pockets are free of foreign material, and the drive wheel scrapers are adjusted to within 3mm of the drive wheel.

B. Idler and Midroller Condition:

-

- Inspect the condition of the midroller and idler seals. Look for any wet areas indicating a leaking seal.

- Check the condition of the midroller rubber. Replace midrollers if:

- More than 1/3 of the total rubber is missing around the entire midroller.

- All the rubber is missing at any point all the way across the midroller.

- Any flat spots are seen, which may indicate the midroller has stopped turning.

C. Idler Condition:

-

- Check idlers for missing rubber or for cracks at the bolt holes. Use similar criteria as midrollers to determine if idlers should be replaced due to loss of rubber.

D. Updates to Consider Before Installing New Tracks:

- Idler Pivot Bushings: Check the idler pivot bushings for wear. If loose, the track will not stay aligned, and premature drive lug damage may result. Replace if necessary.

-

- Drive Wheel Scrapers: Ensure the machine is equipped with drive wheel scrapers and that they are adjusted correctly to 3mm clearance without contacting the wheel. Properly adjusted scrapers remove debris build-up on the smooth surface of the drive wheel, which can reduce drive lug and inner track life. Consult with your CNH dealer for part numbers and quantities for specific machines.

-

- Check the old tracks: Examine the old tracks prior to removal for wear characteristics that may indicate what undercarriage components need repair. Check idler and midroller flanges for damage, proper thickness, and cracks – all of which will reduce drive lug and track life.

VI. Installing Your New Rubber Tracks (ROWTRAC, T8 SMARTTRAX)

A. Positioning the Track:

-

- Using a boom truck, forklift with a strap, or CAREFULLY using the tines of a forklift, set the track on top of the drive wheel and then adjust the track so the drive lugs fall into the drive wheel pockets.

- Place a block of wood between the track and forklift tines, and then push the bottom of the track under the midrollers.

- Using pry bars to help work the track under the midrollers is acceptable if no forklift is available.

B. Working the Track Over the Idlers:

-

- Work the track over the front and rear inside idler wheels carefully, using a forklift or pry bars.

- Applying a soap solution to the inner front and rear idlers may make installation easier.

C. Reinstalling Idler Wheels:

-

- Reinstall the outside front and rear idler wheels.

- Torque wheel bolts to the specified values. Refer to Section II for Rowtrac and T8 Smarttrax values and your operator’s manual for other models.

- Follow an alternate tightening sequence until bolts hold the specified torque.

- Re-torque after the first 3 hours of operation.

D. Tensioning the Track:

-

- Raise the machine off the jack stands and remove the jack stands.

- Lower the machine.

- Start the engine.

- Select a hydraulic remote valve and hold it stroked for 15-30 seconds to observe the track tensioner fill and the track tension increase to operational values.

VII. Track Alignment (ROWTRAC, T8 SMARTTRAX)

A. Checking Alignment:

-

- Drive the machine straight ahead at not faster than 5 MPH on a flat surface, with no steering input, for a distance of at least 400 feet.

- Coast to a stop without steering or braking.

- Using your hand, observe the temperature difference between the two outside faces of the drive lugs.

- If a noticeable temperature difference is felt by hand and/or one side of the drive lugs are shiny or shows signs of rubbing, then an alignment adjustment is needed.

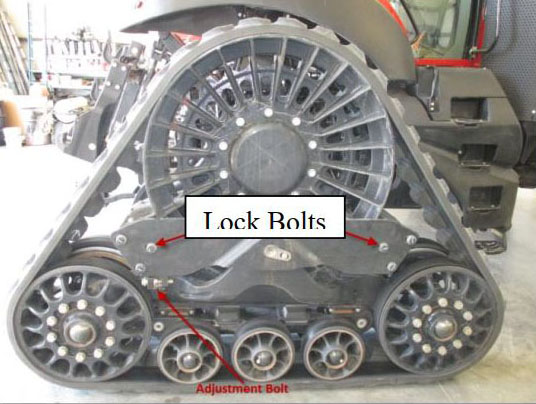

B. Adjusting Alignment:

-

- The alignment adjustment is made by moving the alignment plate (yoke plate) on the undercarriage.

- Loosen the 3 front and 3 rear alignment plate bolts just enough to allow the washer to spin free.

- Turn the adjustment bolt (refer to diagrams in your service manual for location) at least 1 full turn to move the alignment plate either forward or rearward.

- To move the track INWARD, adjust the alignment plate rearward.

- To move the track OUTWARD, adjust the alignment plate forward.

- Retighten the 6 alignment plate bolts to 500 -585 ft-lbs. Always verify torque values in your operator’s manual.

- Recheck track alignment and repeat steps as needed.

C. Final Alignment Check:

-

- Once the initial alignment is completed, conduct a final alignment check.

- Drive the tractor in a straight line at moderate speed (10mph – 15mph) without steering input for approximately 1/4 mile.

- Stroke a remote function for 15 seconds while driving to ensure tracks are tensioned properly.

- Using your hand or an infrared temperature gun, verify the outside faces of the drive lugs are similar in temperature, indicating a properly aligned track.

- If one side of the drive lugs is significantly warmer than the opposite sides (20 degrees F or more differential), make small adjustments to “fine tune” the track alignment.

- Loosen the alignment plate bolts and move the adjustment bolt 1/2 turn in the proper direction.

- Tighten and torque the alignment plate bolts to 500 -585 ft-lbs.

- Repeat the driving test and adjust if needed until the temperatures of the drive lug outside faces are similar (within 20 degrees F) on both sides.

- It is recommended that alignment be rechecked after 10-20 hours of operation.

VIII. Conclusion

Properly replacing and maintaining the rubber tracks on your Case IH Rowtrac and New Holland T8 Smarttrax equipment is essential for ensuring its longevity and performance. By following this step-by-step guide, you can confidently perform these procedures, minimize downtime, and maximize your machine’s productivity. Remember to always prioritize safety and consult your operator’s manual for model-specific information and torque values. For further assistance or to explore a wide range of high-quality agricultural rubber tracks, please visit the Nissitrac website or contact our support team.